RUMP STRAHLANLAGEN

We have been developing and building customized shotblasting machines since 1969.

What is behind RUMP STRAHLANLAGEN?

Behind the brand RUMP STRAHLANLAGEN is the family business RUMP STRAHLANLAGEN GmbH & Co. KG, established by Konrad Rump in 1969 in Salzkotten, Germany and now run by his son-in-law Marcel Adriano.

With more than 48 years experience in the field of shotblasting and surface technology, RUMP STRAHLANLAGEN provides high quality and safety for various sectors and their requirements.

What does RUMP STRAHLANLAGEN offer?

The offer ranges from the planning and manufacturing of customized shotblasting machines in compressed air and airless blast cleaning procedures from one source up to spare part services as well as machine maintenance and care.

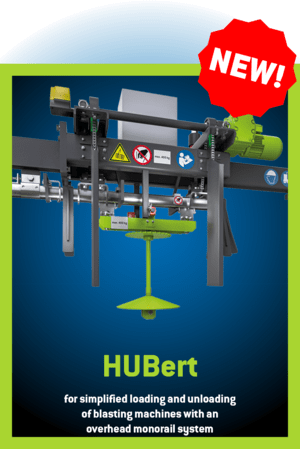

In addition to the classical machine types like wire belt, overhead monorail shotblast machines and roll conveyors, airblast cabinets or sand-blasting shops, pipe shotblasting machines for inner and outer machining of pipes as well as tumble shotblasting and steel mill tumble belt machines for blasting batch-processed workpieces are also supplied. In addition, RUMP STRAHLANLAGEN with its innovative compact systems provides the opportunity to respond to customer requirements quickly and efficiently.

All systems are manufactured with high material quality, to ensure long service life. Likewise, great emphasis is placed on low energy consumption, efficient use of blasting abrasive as well as convenient maintenance, to provide all customers with competitive advantages.

Another service provided by RUMP STRAHLANLAGEN is the retrofit of shotblasting machines. This means the technical modernization or upgrading of older machines to generate higher productivity. This is also possible for other products.

Who are the customers of RUMP STRAHLANLAGEN?

You as the customer have a particular application – RUMP STRAHLANLAGEN has the appropriate solution. Many companies from various industries, like for example foundries, forges and metal or steel processing companies already use RUMP products successfully for their manufacturing applications.

But the metalworking sectors - the automotive industry as well as the vehicle production, shipbuilding and toolmaking industry - also benefit from RUMP blasting solutions. Users from the spring industry, hardening plants and companies from the spraying and coating sector rely on the experience of RUMP STRAHLANLAGEN.

Different application scenarios

Shotblasting technology is always used for surface treatment for cleaning purposes or for preparation for subsequent processes.

This includes removal of manufacturing-related contaminations of workpiece surfaces like for example the black tinder skin on rolled steel or forged products, moulding or core sand residues for cast parts or rust layers for many ferrous alloys as well as the removal of old coating layers or contaminations during reprocessing.

Additional application scenarios are strain hardening and application of compressive stress to the metal surface during the so-called shot peening for example of springs in order to slow down the formation of stress cracks, as well as the rounding of sharp ridges and edges which occur during different mechanical and thermal separation processes as well as the blasting of thermally ashed painting racks following pyrolysis.

A standard applies to the preparation of surfaces for subsequent coating, describing different degrees of purity and providing photographic models of rolled steel surfaces with different initial and blasting states for optical comparison. In this context, the slight roughening of galvanized steel surfaces during sweeping in preparation for a so-called duplex coating is to be mentioned. Surfaces to be adhered, like for example brake lining support plates, are blasted first to improve adhesion.

Blasted workpieces of steel can be welded more easily due to the hard oxide layer being removed, and create less wear of the subsequently used tools for metal-cutting operations.

And RUMP STRAHLANLAGEN supplies all this from a one-stop shop?

Yes, as we can rely on the know-how of 90 experts in our company, who are committed to shotblasting machines: Engineers, technicians, electronics engineers, industrial mechanics and experienced businesspeople work together with the owner family at the site in Salzkotten to produce their blasting solution, rendering RUMP STRAHLANLAGEN a supplier of high quality.

You are very welcome to visit us and get an impression of RUMP STRAHLANLAGEN on site, and learn what sets us apart from other shotblasting machine manufacturers.